R&D Platform

Since its establishment, Goldpro has attached great importance to research and development innovation, investing a large amount of manpower and funds in the continuous research and development of new materials, new processes, new equipment, and new products. It has a R&D team of more than 60 people, including 2 academicians and 11 experts and professors. A high-level technological innovation team led by academicians has been established. The company's innovation team has been awarded the Hebei Province "Giant Plan" Innovation and Entrepreneurship Team by the Hebei Provincial Committee and Provincial Government, the Hebei Provincial Excellent Innovation and Entrepreneurship Team by the Hebei Provincial Science and Technology Department, and the Top Ten Science and Technology Innovation Teams in Handan by the Handan Municipal Committee and Municipal Government.

University-Enterprise Cooperation

The company has established industry-university-research cooperation relationships with seven universities: University of Science and Technology Beijing, Beijing University of Technology, Hebei University of Technology, North China University of Science and Technology, Hebei University of Science and Technology, Hebei University of Engineering, and Jiangxi University of Science and Technology.

Goldpro joins hands

Beijing University of Technology and Hebei University of Technology

New material formula, new material production

Process and matching heat treatment process

Research and Development Achievements

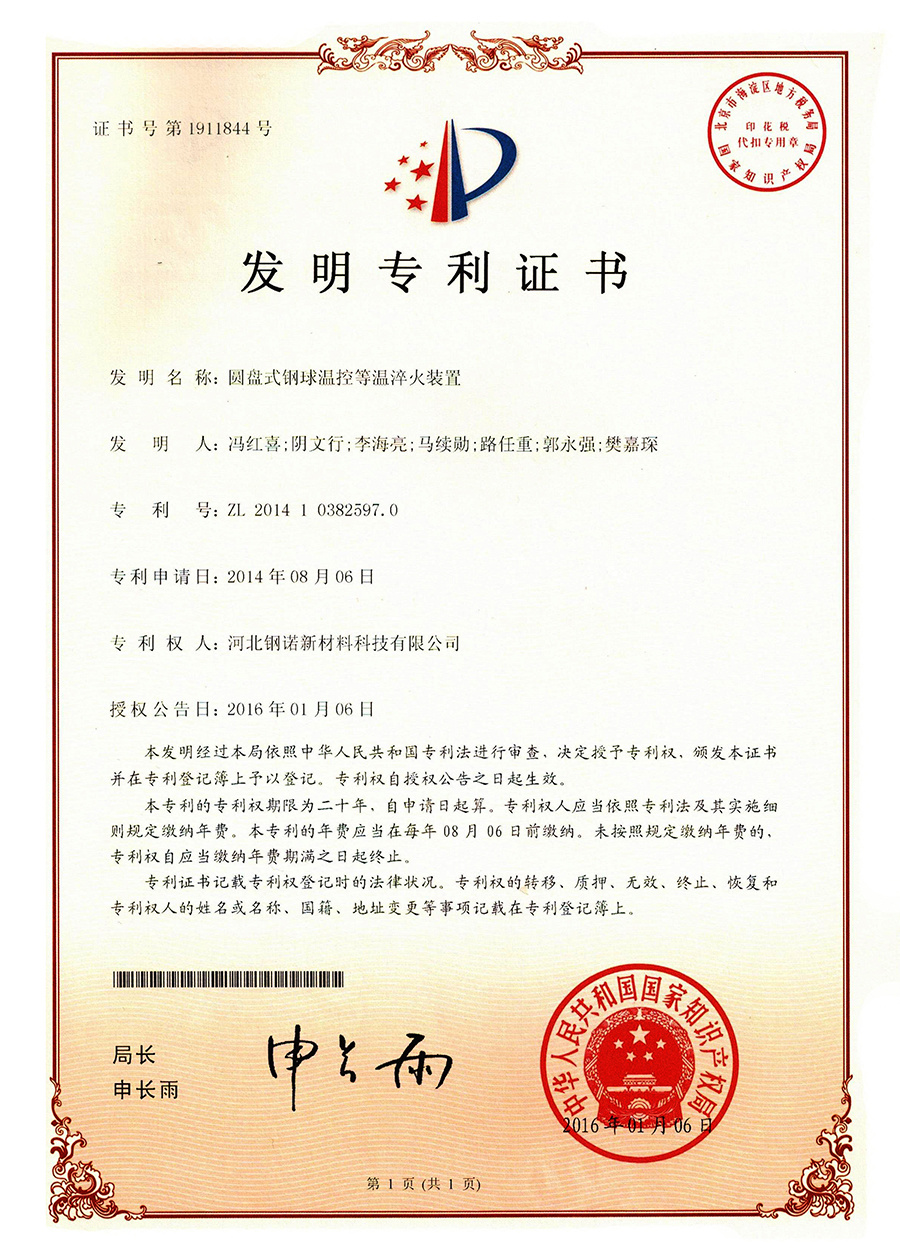

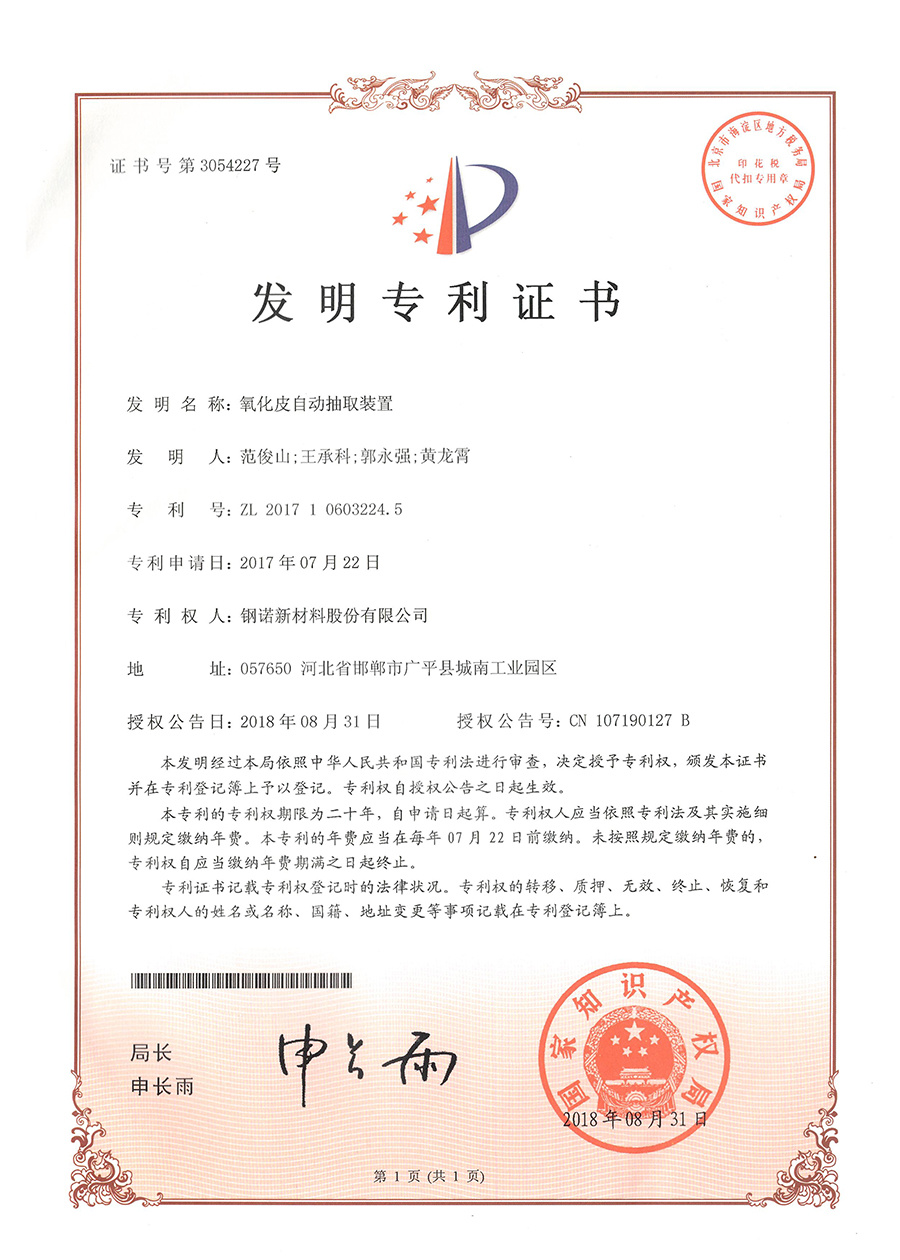

Currently, the company has obtained more than 130 national patents and scientific and technological achievements, and has won numerous scientific and technological progress awards. These R&D platforms and innovative achievements have provided strong technical support for the company's sustainable development and energy saving and emission reduction for customers.

Core advantages

Strictly implementGB/T19001-2016 idt ISO 9001: 2015system, and established a complete product control system, product quality testing system, and product traceability system.

It possesses internationally authoritative quality testing equipment, such as Thermo Fisher ARL iSpark 8860 direct-reading spectrometer, Wilson ROCKWELL 574 Rockwell hardness tester, Zeiss Axio Lab.A1 microscope, microcomputer-controlled low-temperature automatic impact testing machine, and 10-16m drop ball testing machine.

The concept of "Four Everything"

The "Four Everything" quality concept includes:

Everything is for the sake of the customer, everything is prevention oriented, everything speaks with data, and all work is carried out in a PDCA cycle.

Everything for the sake of customers:We must prioritize customer requirements and standards, and establish the concept of customer first;

Putting prevention first in everything:We are required to establish the concept of prevention first, prevent problems before they happen, and eliminate problems at the budding stage;

Everything speaks with data:Require us to use scientific methods to collect and analyze data, trace the root cause, and identify the essence of the problem;

All work is carried out in a PDCA cycle:We are required to never be satisfied, keep improving, and use systematic thinking to achieve continuous improvement.

The concept of "three complete"

The "three complete" quality concept includes: comprehensive quality management, whole process quality management, and all staff participation in quality management.

Total Quality Management

Total quality management

Quality management is everywhere.

Quality management not only includes product quality, but also needs to comprehensively consider factors such as cost, delivery time, and service, which is truly comprehensive quality management.

Full-process quality management

Whole process quality management

Without a process, there is no result.

Comprehensive process quality management requires us to attach importance to every aspect of the value-added of the enterprise value chain, in order to ensure the final quality results.

Total Quality Management

Full participation in quality management

Quality management is everyone's responsibility.

Everyone should attach importance to product quality, identify problems in their work, and make improvements, taking responsibility for the quality of work results.