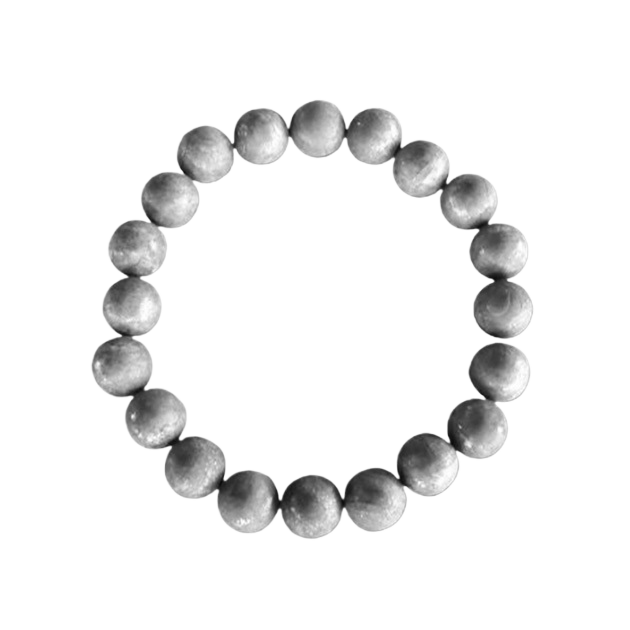

Grinding balls for ball mills (Ф20-Ф100)

Keywords:

Category:

- Product Description

-

Ball mills are key equipment for further pulverizing materials after crushing. Using steel balls as grinding media, they further grind materials to achieve certain fineness requirements and better grinding effects. Most mines use overflow ball mills. Ores and other materials, with the rotation of the cylinder and the movement of the grinding media, are gradually transported towards the discharge end after crushing, and finally overflow from the hollow shaft neck at the discharge end. Therefore, compared with semi-autogenous mills, the mill diameter is smaller, the feed size is smaller, the steel ball size is smaller, the ball mill operating speed is relatively smaller, the filling rate is higher, and the steel balls mainly move in a cascading manner within the mill. Through the impact and grinding of multiple steel balls on the ore, the purpose of crushing and grinding is achieved. Materials and steel balls that have not reached a certain size cannot be discharged from the mill, which requires the steel balls to have high wear resistance. However, due to the complex working conditions inside the mill, when the steel balls are worn to a smaller diameter, deformation and out-of-roundness are inevitable, resulting in reduced grinding efficiency. If the hardness is too high and cannot disappear quickly, it will occupy part of the effective filling rate of the mill, causing energy waste and being unfavorable for energy saving and consumption reduction in mines.

Through in-depth discussion and analysis, and by analyzing and researching the failure mechanism of steel balls, combined with the actual operating conditions of ball mills, Goldpro New Materials Co., Ltd. has developed special Grinding balls for ball mills through research and development of steel ball materials and matching heat treatment processes. The steel balls have high hardness and good wear resistance within the effective volume, while the hardness is appropriately reduced at a smaller diameter, ensuring that the grinding effect is not reduced while reducing the waste of the effective filling rate in the ball mill, thereby improving the grinding efficiency and contributing to energy saving and consumption reduction in mines. Through actual use in a large-scale mine abroad, steel ball wear has been reduced by 15%~20%, and the mine has significantly increased production and efficiency, which has been fully recognized by mine leaders and employees.

Get a quote now

Please feel free to leave a message, and we will reply to you within 24 hours.

Related Products