Grinding cylpebs

Keywords:

Category:

- Product Description

-

Unlike steel balls, steel rods have a flexibility in rotation during the grinding process that lies between that of a sphere and a rod, primarily relying on line contact to crush minerals. When using steel rods as the grinding medium, the products of various particle sizes are relatively uniform, exhibiting a certain selectivity in the grinding of intermediate products and offering a degree of protection to the minerals. This fully leverages the advantages of rod milling, although the crushing force is less than that of spherical grinding. Steel ball milling grinds through point contact with the material, suitable for fine grinding with good results, but it does not protect the material and easily causes over-grinding. The yield of various particle sizes in steel ball milling is not as uniform as with steel rods. Therefore, to ensure grinding fineness while maintaining uniform particle size distribution, many mines adopt a mixed addition method of simultaneously adding steel balls and steel rods when replenishing grinding media to achieve good grinding results.

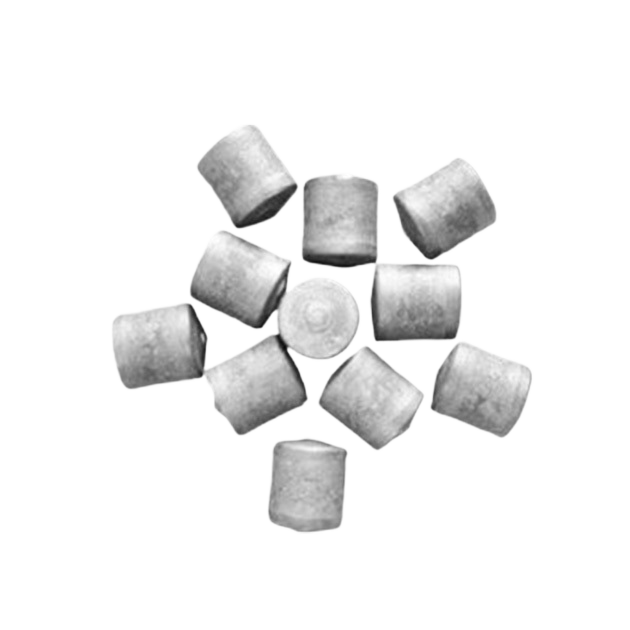

Currently, steel rods on the market are produced using casting, forging, and direct shearing processes. The characteristics of the casting process result in a product with a less dense structure, and to facilitate mold removal, they are typically conical steel rods. The forging process maintains the density of the raw material in the structure, but often results in an S-shaped rod, affecting linear contact and hindering comprehensive and efficient grinding. The sheared horseshoe shape also affects the running trajectory and grinding contact surface of the steel rods, reducing grinding efficiency.

Through long-term dedicated research, Goldpro New Materials Co., Ltd. has successfully developed a high-efficiency rolling process and complete set of equipment, integrating the advantages of the above processes. This produces rolled steel rods in a capsule shape, with the grinding effect of steel balls at both ends and a straight rod body for good linear contact. The stable running trajectory during the grinding process results in high and effective overall grinding efficiency. To further improve customer usage, our company continuously develops special materials and supporting heat treatment processes for steel rods, forming a series of steel rod products with various specifications and materials, such as 20mmX30mm…70mmX80mm. We can also customize various non-standard steel rods according to mine operating conditions and customer requirements to meet grinding needs.

Get a quote now

Please feel free to leave a message, and we will reply to you within 24 hours.

Related Products