ABOUT US

Goldpro New Materials Co., Ltd.

Goldpro New Materials Co., Ltd. is located in the South Industrial Park of Guangping County, Handan City. Established in June 2010, with a registered capital of 200.3 million yuan and 260 employees, the company is a national high-tech enterprise, a national intellectual property demonstration enterprise, a national specialized and new "small giant" enterprise, a leading enterprise in Hebei Province's industrial cluster, a leading enterprise in Hebei Province's county-level characteristic industrial cluster, a Hebei Province technological innovation demonstration enterprise, a Hebei Province management innovation demonstration enterprise, a top 100 innovative enterprise in Hebei Province's strategic emerging industries, a Hebei Province manufacturing single-item champion enterprise, a Hebei Province foreign trade brand advantage enterprise, a Hebei Province quality and efficiency-oriented enterprise, a Hebei Province contract-abiding and credit-worthy enterprise, a top 100 private enterprise with invention patents in Hebei Province's technological innovation, an excellent leading enterprise in Handan City's characteristic industrial cluster, and a leading technological enterprise in Handan City. The company is the chairman unit of the Hebei Provincial Strategic Alliance for Technological Innovation in the Ball Mill Steel Ball Industry. The company's scale ranks first in Hebei Province and second in China in the same industry.

Goldpro specializes in the production of wear-resistant grinding balls, grinding cypebs, grinding rods for various industries including mining, thermal power, and construction materials. Goldpro currently possesses leading forging and rolling production lines both domestically and internationally, with an annual production capacity of 400,000 tons. Goldpro serves as a technology research and development base for large-diameter semi-autogenous mill specialized steel balls in China. The products have been sold in 25 provinces, municipalities, and autonomous regions in China, as well as exported to over 20 countries and regions including Chile, South Africa, the United States, Ghana, Brazil, Peru, Mongolia, Australia, Russia, Kazakhstan, and the Philippines.

The company has established production, education, and research cooperation relationships with seven universities, including Beijing University of Science and Technology, Beijing University of Technology, Hebei University of Technology, Hebei University of Science and Technology, Hebei University of Engineering, North China University of Science and Technology, and Jiangxi University of Science and Technology. It has established research and development innovation platforms such as the Hebei Provincial Steel Ball Technology Innovation Center and the Hebei Provincial Enterprise Technology Center. It is a Class A R&D institution for industrial enterprises in Hebei Province and has taken the lead in establishing the Hebei Provincial Steel Ball Industry Technology Innovation Strategic Alliance. The company owns more than 100 technical patents and core achievements. It is the leading drafting unit of the Hebei Provincial Local Standards for "Mining-Specific High Wear-Resistant Forged (Rolled) Steel Balls", "Rod Mill-Specific Wear-Resistant Steel Rods", and "Testing Method for Hardness of Forged (Rolled) Steel Balls: Rockwell Hardness".

Company established in

Factory area

Annual output

Exporting countries and regions

Corporate Culture

Building a Technological Aircraft Carrier for Grinding Media, Creating Exceptional Value for Customers.

Forging Excellence in grinding media, Building a Century of Goldpro, and Creating a Global Brand

Brand Philosophy: Tempered Steel of Quality, Trustworthy Promise of Gold

Business Philosophy: Innovate Customer Value, Achieve Common Growth

Management Philosophy: Manage with Systems, Unite People with Culture

Evaluation Philosophy: Evaluate Ability by Results, Determine Compensation by Contribution

Talent Philosophy: Professional, Dedicated, and Responsible

Corporate Philosophy

Brand Philosophy

Forging quality steel

Reputation is worth a thousand gold

1

Business Philosophy

Innovate customer value

Achieve common growth

2

Management Philosophy

Manage with regulations

Unite people with culture

3

Evaluation Philosophy

Ability judged by results

Compensation determined by contribution

4

Talent Philosophy

Professionalism, dedication, commitment

Do your best, take responsibility

5

Development History

So far

2024

On January 28, Feng Hongxi, chairman of Gangnuo New Materials Co., Ltd., was elected "Handan Private Enterprise Star".

On January 17, the company was awarded "2022-2023 Hebei Province Typical Case Enterprise of Integrity".

2023

On February 15, reporters from Xinhua News Agency visited Goldpro.

April 20, the TV station filmed and promoted for specialized, refined, unique, and new "little giant" enterprises

June 13, Gangnuo Company Information System Project Launch Meeting

October 30, provincial leaders (Governor Hu Qisheng) and his delegation visited the company for research, accompanied by county and city leaders. General Manager Feng, Teacher Wang Baoqi, and others received them and introduced the company's basic situation and development direction

Year 2022

In June, the company was awarded "Excellent Enterprise of Handan's Characteristic Industrial Cluster".

In August, the company was awarded "Handan's Leading Science and Technology Enterprise".

2021

January: Awarded as a national specialized and new "small giant" enterprise

January: Awarded as a Hebei Province "specialized and new" demonstration enterprise

April: Awarded the "National May 1 Labor Award" by the All-China Federation of Trade Unions

October: Awarded "Top 100 Private Enterprises for Technological Innovation and Invention Patents in Hebei Province, 2021"

October: Awarded "Hebei Province Enterprise of Integrity Construction"

December: The intelligent production line of the production center was put into operation, with a daily output of 90 tons of φ125 steel balls

2020

In March, won the first prize of Handan Science and Technology Progress Award

In July 2019, the company was awarded the honor of "Manufacturing Single Champion".

In September, the world's largest drop ball testing machine was completed and put into use

In November, the industry's first intelligent production line and data center were completed and put into operation, marking the company's entry into the era of informationization and intelligence

2019

In March, established offices in Eurasia, Southeast Asia, and West Africa

In March, opened new markets in mines under Guocheng Group and Western Mining, receiving consistent praise from clients in our collaborations.

In July, entered the main board listing guidance period.

In July, established a cooperative relationship with BHP's Escondida mine in Chile, further enhancing our brand recognition in the South American market.

2018

In August, new markets were opened with CICC Group Huatai Long Mining and Zijin Group Duobaoshan Copper, receiving consistent praise from clients.

In August, a cooperative relationship was established with Sierra Gorda, KGHM Group's largest mine in Chile, laying a solid foundation for entering the Chilean market.

2017

In March, a comprehensive strategic partnership was established with Zijin Mining Group, successfully entering the state-owned enterprise overseas market.

In June, long-term cooperative relationships were established with China Railway Lu Ming and Jiu Steel Group.

In June, a major technological breakthrough was achieved, developing large-specification 160mm steel balls, promoting the realization of the R&D strategy of "developing one generation, using one generation, and reserving one generation".

In June, products entered the Russian market.

In September, a South American office was established.

In December, a cooperative relationship was established with Buenaventura, a century-old Peruvian mining company, marking an important chapter in the strategic deployment in South America.

2016

In January, a school-enterprise cooperation agreement was signed with Jiangxi University of Science and Technology, establishing a cooperative relationship.

In March, the company name was changed from "Hebei Gangnuo New Materials Technology Co., Ltd." to "Gangnuo New Materials Co., Ltd."

In July, Gangnuo New Materials was listed on the NEEQ (National Equities Exchange and Quotations).

In October, it was identified as the "Hebei Province Ball Mill Steel Ball Engineering Technology Research Center" and officially unveiled.

In November, a cooperation agreement was signed with Tsinghua University, establishing a cooperative relationship.

In December, a Beijing office was established.

2015

In April, the "Gangnuo" and "Goldpro" trademarks were registered in Chile.

In July, jointly drafted and formulated the Hebei Provincial Local Standard (DB13/T 2197-2015) for "wear-resistant steel bars for rod mills" with the Guangping County Quality and Technical Supervision and Inspection Institute.

2014

In January, a cooperation agreement was signed with Hebei University of Science and Technology to establish a cooperative relationship

In March, jointly drafted and formulated the Hebei Provincial Local Standard (DB13 / t1833 - 2013) for "forged (rolled) steel balls for mining" with the Guangping County Quality and Technical Supervision and Inspection Institute

In June, products entered the African market

In August, products entered the Australian market

In September, the "Goldpro" trademark was successfully registered in Australia

In November, passed the quality management system, occupational health and safety management system, and environmental management system certifications

2013

In January, the company name changed from "Hebei Gangnuo Metal Products Co., Ltd." to "Hebei Gangnuo New Materials Technology Co., Ltd."

In January, a cooperation agreement was signed with Hebei University of Technology, establishing a cooperative relationship.

In March, the "Gangnuo" trademark was registered.

In November, it was recognized as a national high-tech enterprise.

2012

January: First export of steel balls to the Fiji Islands

July: Establishment of an academician workstation

2011

January, signed a cooperation agreement with Beijing University of Science and Technology, establishing a cooperative relationship

March, Hu Zhenghuan, professor, doctoral supervisor, and academician of the Chinese Academy of Engineering at Beijing University of Science and Technology, led a team to provide on-site guidance to the company for the first time

January, signed a cooperation agreement with Beijing University of Science and Technology, establishing a cooperative relationship

2010

In June, Hebei Gangnuo Metal Products Co., Ltd. was registered and established

In August, factory land was requisitioned in the Guangping County South Industrial Park, followed by planning, design, and construction.

-

Digital Factory

It has the first intelligent production line in the industry, with stable product performance and high production efficiency.Contact Us + -

Green Factory

Goldpro attaches great importance to environmental protection development, adheres to low-carbon development and healthy development, and creates sustainable value for societyLearn More +

Intelligent equipment

Independently developed production equipment

The company has independently developed industry-leading intelligent production lines and introduced the MES production management system, realizing full-process production monitoring and real-time data recording, ensuring high efficiency, low cost, and stability of product production. The performance indicators of the company's core products all exceed industry standards and similar domestic products. It owns the industry's first intelligent production line, with stable product performance, high production efficiency, leading equipment technology in the industry, and a total production capacity of up to 400,000 tons.

Efficient production

Mechanical arm

Intelligent equipment

Forging press

Core advantages

Since its establishment, the company has adhered to the corporate mission of "building a technological aircraft carrier for wear-resistant materials and creating excellent value for customers." It has been deeply involved in the field of wear-resistant materials, adhering to market orientation and technology leadership. Through continuous technological research and development and service system innovation, it has gradually formed the company's unique competitive advantages.

Intelligent devices

Possessing the industry's first intelligent production line, the products are stable in performance and high in production efficiency. The equipment technology is industry-leading, with a total production capacity of 250,000 tons.

Self-developed production equipment

Independently developed an industry-leading intelligent production line, introduced the MES production management system, realized the full process monitoring and real-time data recording of production, ensuring high efficiency, low cost and stability of product production. The performance indicators of the company's core products all exceed industry standards and similar domestic products.

Tailor-made raw materials

Tailor-made wear-resistant metal material formulas are provided based on different customer operating conditions to meet the needs of different customers.

Matching heat treatment process

Match different heat treatment processes according to different raw materials and product characteristics to achieve optimal product performance.

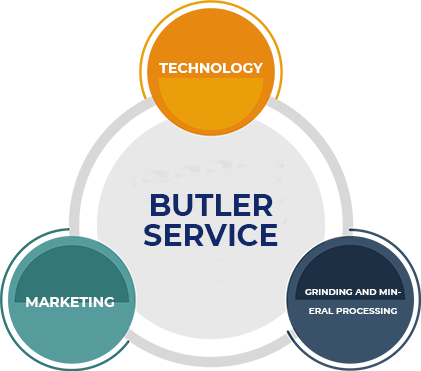

Service advantages

Pioneering the butler-style service model of 'Technology + Marketing + Crushing and Grinding Mineral Processing Solutions

Provides differentiated crushing and grinding selection technology optimization services for gold, silver, copper, molybdenum, iron and other metal mines. It is the company's most core technical service capability, leading the crushing and grinding beneficiation technology towards high efficiency and intensive development, and continuously creating excellent value for customers.

Brand advantages

Since 2016, the company has successively become a high-quality supplier of domestic and foreign mining giants.

China Nonferrous Metal Mining Group Co., Ltd.

China Aluminum

China Railway Construction Corporation

China Minmetals

BaoWu Resources

Zijin Mining

China Gold

China Steel Group

Rio Tinto

Polish copper

Kazakhstan Copper Company

Barrick Gold

BHP

Chilean National Copper Mine

Glencore

Ghana Goldfield

Western Australian gold

Honors and qualifications

Factory area display

In order to achieve the goal of green development, the company starts from multiple dimensions, including infrastructure construction, management system optimization, efficient use of energy and resources, improvement of product environmental performance, reduction of environmental emissions, and improvement of overall performance rating. Following the principles of "factory integration, harmless raw materials, clean production, waste resource utilization, and low-carbon energy," it is committed to building a green and environmentally friendly factory.

Full view of the plant area

Full view of the plant area

Company night view

Video center

Safety Production

Public welfare activities

Public welfare activities