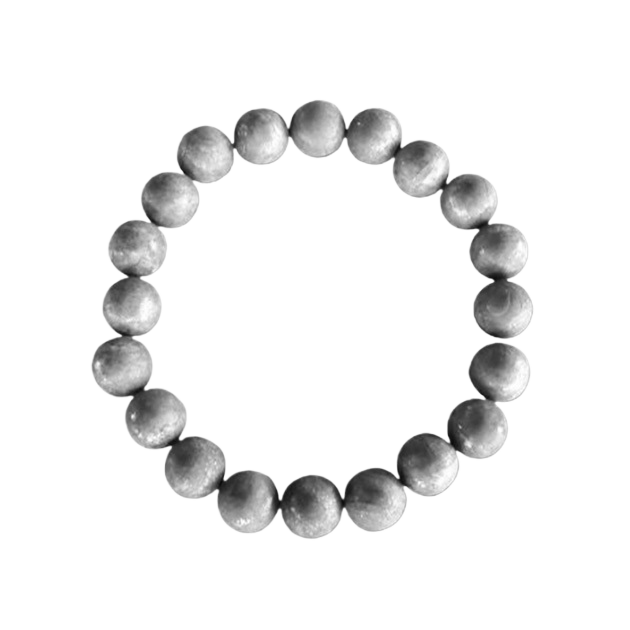

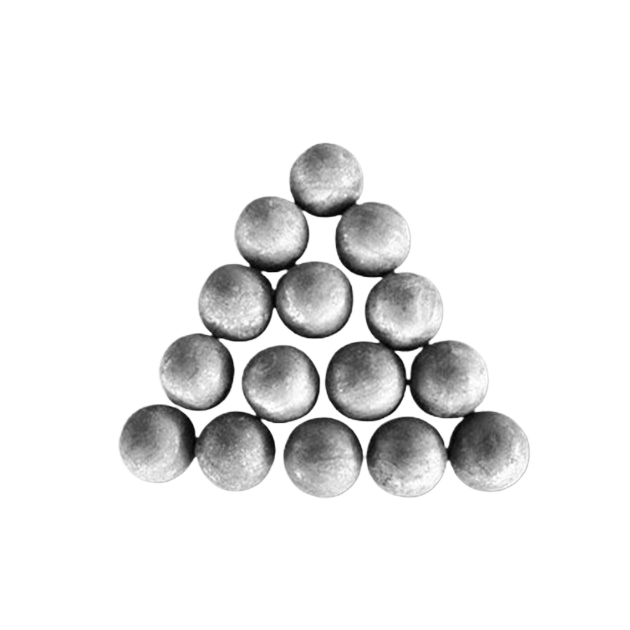

Grinding balls for SAG mill (Ф100-Ф200)

Keywords:

Category:

- Product Description

-

Semi-autogenous grinding (SAG) is a form of autogenous grinding where the grinding media consists of both ore and added steel balls. The two types of media, and their interaction with the liner, impact, slide, and compress, grinding the ore. The feed size is generally 200-350mm, and the product size after a single grinding stage can reach a few millimeters or less. The high reduction ratio significantly shortens the process, offering significant advantages in terms of space saving, reduced capital investment, staffing, and maintenance. Currently, SAG mills in mines are developing towards larger sizes, with mills as large as 12.2m in diameter now in use, greatly increasing ore processing capacity.

The main forces involved in crushing ore inside a SAG mill include the impact force of ore and steel balls during free fall, the grinding and abrasion between particles and steel balls, and the instantaneous stress caused by the sudden change from compressive to tensile stress in the ore. The continuous rotation of the mill keeps larger ore pieces in the inner rotating layer (closer to the mill center), while smaller particles migrate to the outer layer for self-grinding, media grinding, or mutual grinding. Larger diameter steel balls generate greater gravitational potential energy, causing impact, abrasion, and crushing of the ore. Therefore, steel balls for SAG mills typically have a larger diameter, ranging from 120-150mm in most SAG mills. Based on the working principle of SAG mill ore crushing, the steel balls must have good impact resistance and high wear resistance. Good impact resistance prevents breakage of the steel balls due to strong impact forces, which would significantly reduce grinding efficiency, while high wear resistance reduces steel ball consumption, improves production efficiency, and lowers grinding costs.

Goldpro New Materials Co., Ltd. is dedicated to developing steel for SAG mill steel balls and the associated ball forming and heat treatment processes. The company possesses independently developed fully automated heat treatment equipment and production lines, both domestically and internationally. The products are characterized by "three strong and one low": strong stability, strong impact resistance, strong applicability, and low wear. In use at numerous large mines domestically and internationally, the products have demonstrated excellent results in increasing production, improving efficiency, saving energy, and reducing consumption, receiving consistent praise from customers worldwide.

Get a quote now

Please feel free to leave a message, and we will reply to you within 24 hours.

Related Products