Grinding rods

Keywords:

Category:

- Product Description

-

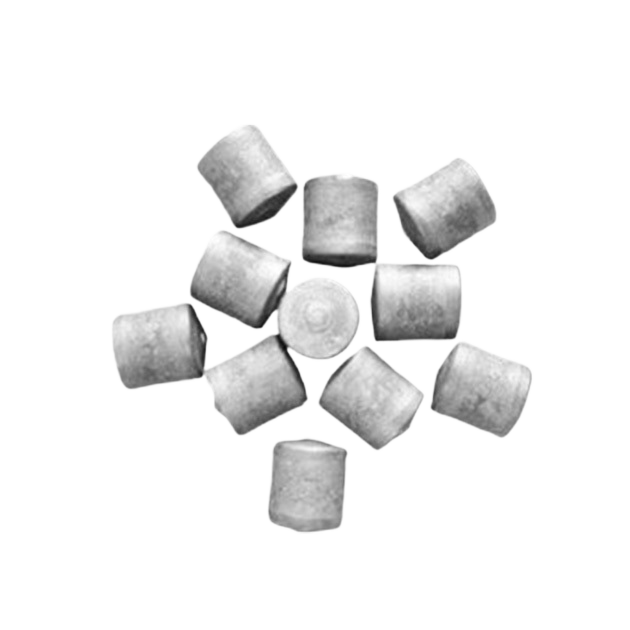

As grinding media in rod mills, wear-resistant steel rods operate in a cascading manner, with regularly arranged rods impacting and crushing minerals in the gaps to achieve the required particle size. Simultaneously, the rods themselves are worn down by the minerals, gradually reducing in size until they are removed from the mill when they fall below a certain size. During actual rod mill operation, the rods constantly receive impact, and insufficient toughness can easily lead to rod breakage. Once breakage occurs, the regular arrangement of other rods in the mill is disrupted, causing rod chaos and leading to more breakage. Therefore, rod breakage not only seriously affects grinding efficiency but also causes equipment damage, leading to shutdowns and severely impacting the normal production of the mine.

Rod production typically involves medium-frequency induction heating followed by heat treatment. Currently, commonly used rod materials on the market are mainly 40Cr and 42CrMo, common die steels with good toughness and low breakage rates. However, for larger rods, the hardened layer is shallow, only 8-10mm, resulting in poor wear resistance during grinding. Other materials, such as 65Mn, show comparable performance. Japanese researchers have proposed using high-carbon steel for wear-resistant rods with good results, but this requires strict steel mill production processes, and high-carbon steel is prone to metallurgical defects. Addressing the limited suitable materials for rods, Goldpro Company independently developed a new steel for rods and a matching heat treatment process. This maintains high toughness while increasing the depth of the hardened layer. It has been used in several mines domestically and internationally without any rod breakage incidents, exhibiting low wear and significantly improved grinding efficiency.

Get a quote now

Please feel free to leave a message, and we will reply to you within 24 hours.

Related Products