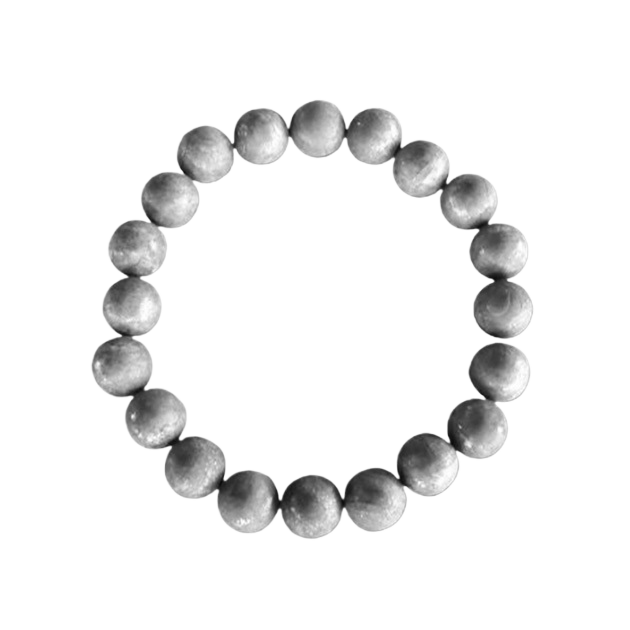

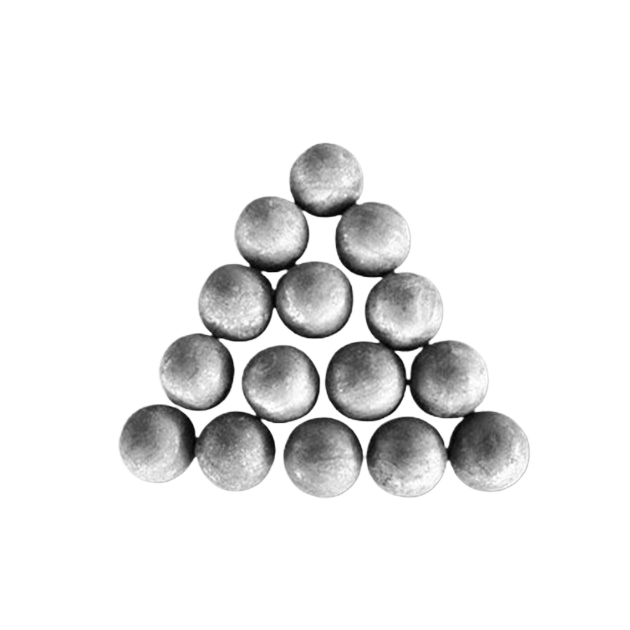

Grinding balls for Initial fill installation (Ф20-Ф200)

Keywords:

Category:

- Product Description

-

Initial grinding mill-dedicated steel balls refer to the steel balls added to the mill before it reaches its design capacity (or normal production). During the semi-trial operation period, due to the debugging stage of equipment, personnel, and operating conditions, the equipment operating parameters and smoothness, the proficiency of personnel operation, and the operating conditions of the mill and steel balls are all in an unstable state. The unstable ore feeding and frequent stops and starts caused by various reasons will lead to frequent and violent impacts between steel balls and between steel balls and liners. The above situations often lead to serious cracking of the steel balls in the early stage of use, greatly reducing the grinding effect; and the impact force on the liners is relatively large, and in severe cases, it will cause the liners to break, significantly reducing the liner life, which will ultimately affect the smooth commissioning of the grinding system and significantly increase the trial production costs.

Goldpro New Materials Co., Ltd., after repeated investigations and experiments, combined with the actual situation of mines, has developed steel balls suitable for initial grinding mill-dedicated steel balls and ball mills, and adjusted the performance of steel balls through improvements in materials and matching heat treatment processes. The produced steel balls have high toughness and certain wear resistance, ensuring that the impact on the liners during the semi-trial operation is reduced, and they can adapt to such extremely harsh operating conditions, without breaking and with certain wear resistance. During the trial operation of the ball mill, they have high wear resistance, do not break, and do not lose their roundness. This avoids affecting the rapid achievement of production targets due to steel ball problems. Through actual use in mines, it has helped customers quickly achieve their production targets and has greatly promoted energy saving and consumption reduction in mines.

Get a quote now

Please feel free to leave a message, and we will reply to you within 24 hours.

Related Products